light cured Metacon system modeling composite

metablue is a light cured modeling composite gel from the syringe, that burns out cleanly and completely and is aligned specifically to be used with the metacon light cured wax system.

quick modeling directly from the syringe

with metablue the metacon system becomes even easier in handling with even more perfect results

PRODUCT DETAILS

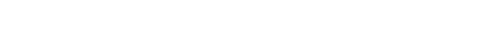

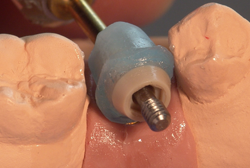

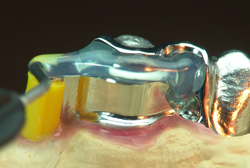

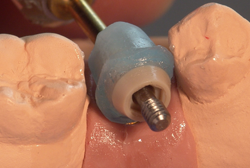

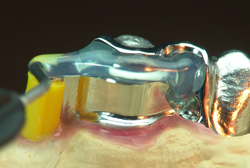

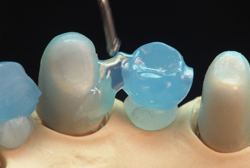

case pictures

uses

- secondary parts of combined cases, such as telescopic or conus crowns, interlocks, RSS, millings, individual attachments, etc.

- individual implant abutments

- tension free connection of Metacon implant bars, bridges or partial segments

- smoothening and/or sealing of ground Metacon surfaces

- fixing of retention beads on secondary telescopic or conus crowns

- easy attaching of the Metacon sprues to the modelled case

advantages

- ready to use, one component material from the syringe, burns out cleanly and completely

- very good and precise modeling characteristics

- connects directly to the light cured Metacon wax

- is processed "cold" – no danger of thermal tension when connecting Metacon segments

- no separator needed on zirconium, metal or porcelain surfaces

- no danger of "melting through" on the block-out or relief wax (in case of partials)

- long working time (>20 min.), short light curing time (<5 min.)

- absolutely precise after polymerisation – no noticeable shrinkage or distortion

- secondary parts can be lifted off without any problem

- easy to grind with conventional carbide burs or universal rubber polishers

product pictures

working procedure

ordering info

metablue

light cured Metacon System modeling composite,

4 syringes at 3g/each, 12 hollow needle tips

Item # : MB100

downloads

product details

- secondary parts of combined cases, such as telescopic or conus crowns, interlocks, RSS, millings, individual attachments, etc.

- individual implant abutments

- tension free connection of Metacon implant bars, bridges or partial segments

- smoothening and/or sealing of ground Metacon surfaces

- fixing of retention beads on secondary telescopic or conus crowns

- easy attaching of the Metacon sprues to the modelled case

- ready to use, one component material from the syringe, burns out cleanly and completely

- very good and precise modeling characteristics

- connects directly to the light cured Metacon wax

- is processed "cold" – no danger of thermal tension when connecting Metacon segments

- no separator needed on zirconium, metal or porcelain surfaces

- no danger of "melting through" on the block-out or relief wax (in case of partials)

- long working time (>20 min.), short light curing time (<5 min.)

- absolutely precise after polymerisation – no noticeable shrinkage or distortion

- secondary parts can be lifted off without any problem

- easy to grind with conventional carbide burs or universal rubber polishers

metablue

light cured Metacon System modeling composite,

4 syringes at 3g/each, 12 hollow needle tips

Item # : MB100